ELECTRICAL KNOWLEDGE

电器知识

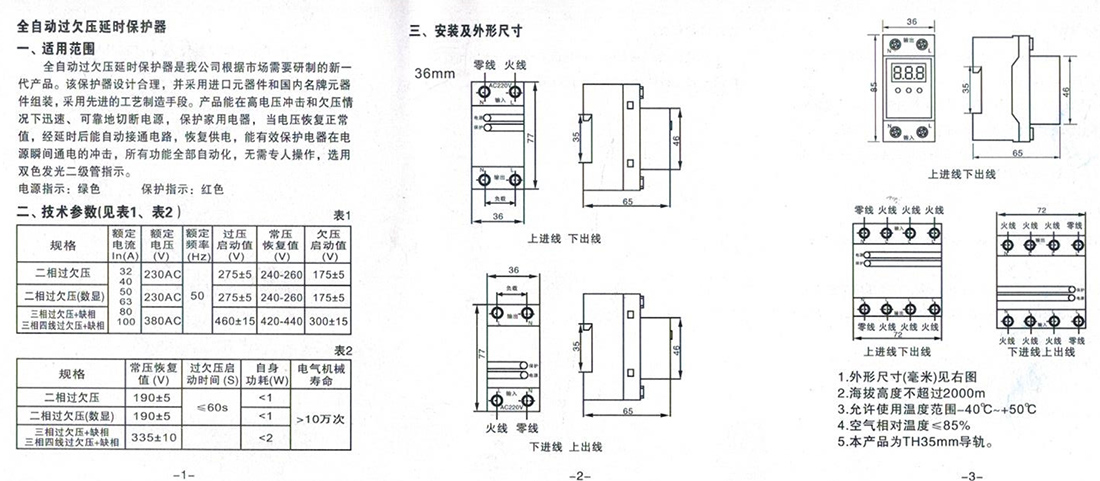

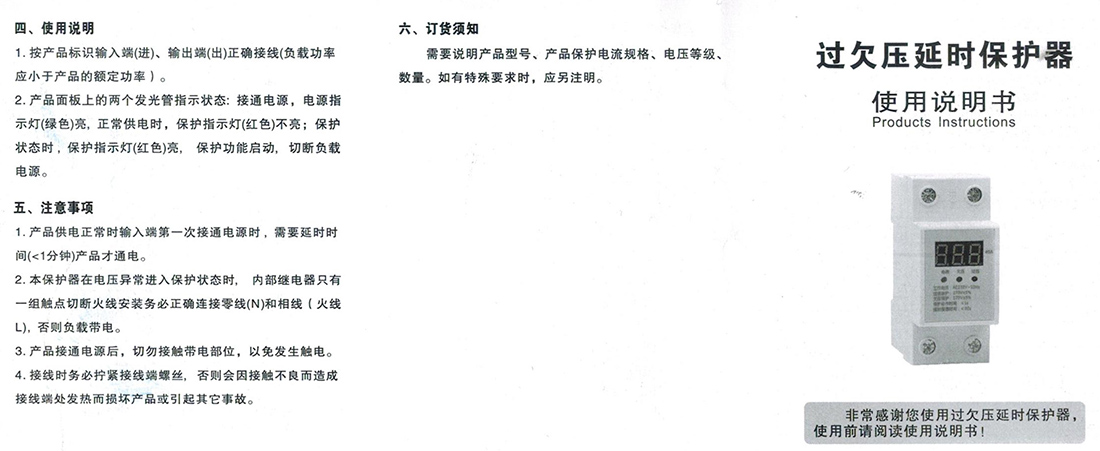

The automatic overvoltage and undervoltage delay protector is a new generation product developed by our company according to the market needs. Quickly and reliably cut off the power supply under shock and undervoltage conditions to protect household appliances. When the voltage returns to normal, the power supply is restored after the delay function is turned on.

Product name: Self-reset overvoltage and undervoltage delay protector

Product number:

RMGQY-63/2P 10A

RMGQY-63/2P 16A

RMGQY-63/2P 20A

RMGQY-63/2P 25A

RMGQY-63/2P 32A

RMGQY-63/2P 40A

RMGQY-63/2P 50A

RMGQY-63/2P 63A

RMGQY-100/4P 32A

RMGQY-100/4P 40A

RMGQY-100/4P 50A

RMGQY-100/4P 63A

RMGQY-100/4P 80A

RMGQY-100/4P 100A